GERSHIN ELECTRONICS CO., LTD. is the leading Taiwan manufacturer, supplier and exporter of SMT PCB and assure our clients about the optimum performance. Our products are fabricated using high grade raw material. These are widely used in varied industry applications. It is manufactured in accordance of international norms and standards and can be easily personalized as per client requirement. We offer them at most competitive prices.

SMT PCB

Intelligent rack storage system

All raw materials are monitored by the barcodes and checked before entering the production. Meanwhile, it is integrated within the EPS system and Intelligent Material Warehouse System to improve the efficiency and achieve our quality standards. As a whole,this MES tracks part usage, regulatory inspections,

station control records, pass yield, and material sourcing.

SMT production line- Automated Optical Inspection

High-speed X-RAY pointing equipment for detecting SMT passive component tape reels

The counting processing speed is very fast, and it can detect different types and sizes of materials, which can save personnel's working time and improve the accuracy of material inventory

You can order materials without opening the sealed package to keep moisture-proof

Quantity labels can be printed immediately to avoid handwriting errors

Ultrasonic steel plate cleaning machine

Due to the long-term printing of solder paste on the steel plate, there will be residual solder paste and impurities, which will affect the printing quality, and then because the residual flux on the steel plate will be cleaned, a cleaning solvent will be used, and excessive contact should be avoided

The steel plate cleaning machine has a high-efficiency and low-pollution working mode,

Ultrasonic vibration cleaning can penetrate deep into the dead corner of the object, and the cleaning effect is good.

Reduce manual cleaning operations, simplify cleaning procedures, and improve work safety

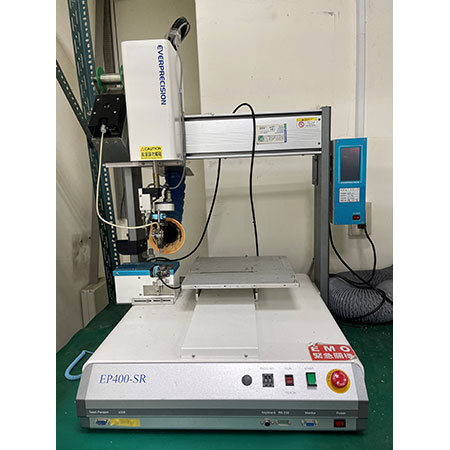

EP400SR

Automatic soldering machine Automated soldering can greatly reduce labor costs and replace the unstable production capacity caused by manual soldering

The high-power temperature control system equipped on the automatic soldering machine can quickly and accurately heat up. The "soldering iron real-time temperature compensation function" during the soldering process and the matching of various types of special-purpose soldering iron tips provide good soldering quality for the soldered objects

Precisely control the amount of tin, and adjust the perfect welding angle and position according to the welding material, which can improve the quality and work efficiency

We value every client's comments about our

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文